Description

Standard Features

• Mechanical liquid inlet valve provides positive control of LP-Gas liquid level on all RW100 units. RW180 thru RW900, use a reliable float switch and electric inlet valve to prevent liquid carryover.

• Millivolt-powered gas control system maintains proper water bath temperature under changing load conditions.

• Gas control valve is located inside the protective dry cabinet with the regulator mounted on the exterior providing for total ventilation.

• Precision operating temperature switch, factory-set and tamper resistant, incorporates precious metal contacts for extended service life.

• Two-stage pressure regulation provides accurate burner gas burner pressures and performance regardless of changes in inlet pressure.

• ASME code vaporizing tubes with integral heat exchange vanes and internal water chamber provide efficient vaporization with minimum burner input.

• Integral circulating pumps enhance heat transfer and temperature control capabilities.

• Modular design provides maximum capacity in a compact, rectangular unit.

• Double-Louvered combustion air baffles assure freedom from outages even during adverse weather conditions. (For extreme conditions, optional electric pilot reignitors are available).

• All sizes are capable of infinite turndown and will maintain a ready supply of vapor from zero load to full capacity. At no load, only enough heat will be generated to maintain water temperature and to prevent condensation.

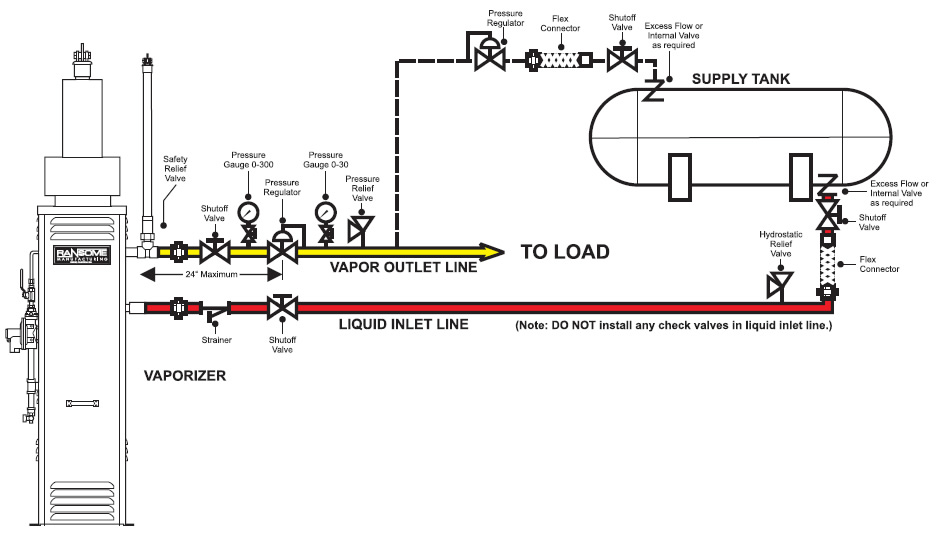

Typical Installation

1. Equipment, piping and installation must be in accordance with provisions of NFPA58, and all applicable state, provincial and local codes.

2. Liquid pump may be required to provide sufficient pressure to inlet of vaporizer during conditions of low tank pressure.

3. Outlet pressure regulator should be no more than 24 inches from vaporizer outlet and located at or above centerline of vaporizer outlet.

4. Do not install a separator, dripleg or other liquid trap upstream of outlet pressure regulator.

5. Regulator outlet pressure must be adjusted to a pressure below the vapor pressure of the saturated LP-Gas at lowest oparating temparature or vapor may re-liquefy in downstream piping.

6. Liquid piping system must allow for occasional reverse flow toward supply tank to prevent excessive pressure during operation.

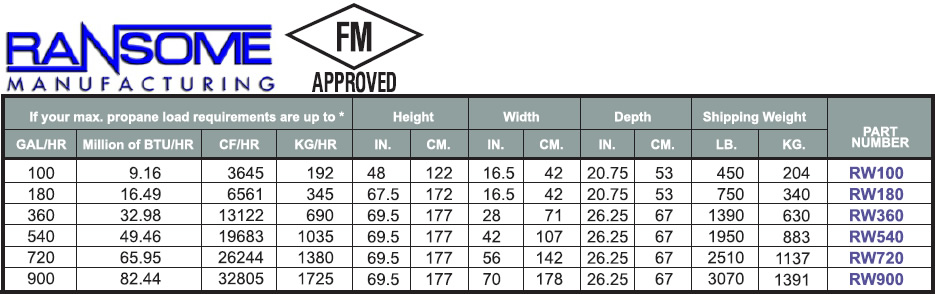

(1) Units may be paralleled to achieve greater capacities

Note: Intermittent Pilot System is standard on all RW Series. For use with other gases, consult factory for sizing information. (i.e. C3H6, NH3, SO2, C12)