Description

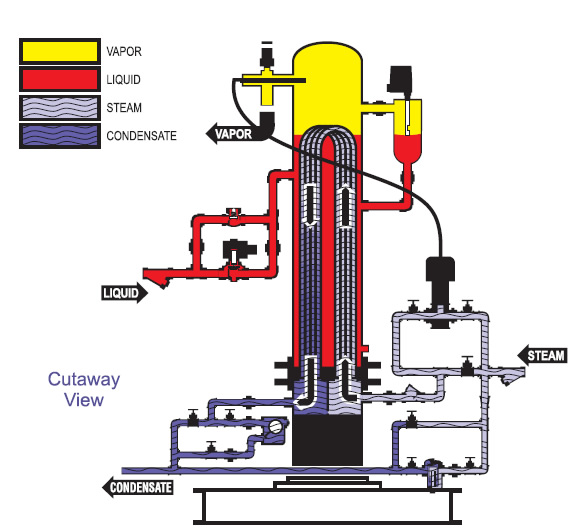

The VS Series Steam vaporizer uses a thermally actuated control system to regulate the flow of steam into a shell and tube heat exchanger. The thermal system consists of a liquid filled diaphragm actuator connected by means of a filled, semi-flexible capillary tube to a partially filled sensing bulb inserted in the LP-Gas vapor stream. As temperature at the sensing bulb increases (as would occur during a low LP-Gas flow condition), the fluid in the bulb partially vaporizes, applies pressure to the diaphragm and closes the valve. As temperature at the sensing bulb decreases (during a higher LP-Gas flow condition), the fluid would re-condense, reducing pressure on the diaphragm and opening the valve. Depending on gas flow conditions, the valve will throttle the flow of steam to maintain the desired temperature range.

Standard Features

• ASME Code Heat exchange pressure vessels. The shell is constructed of rugged carbon steel for high strength and good heat exchange characteristics.

• The removable, field replaceable tube bundle is constructed entirely of stainless steel to ensure long life and corrosion resistence.

• Ransome’s unique liquid level float configuration. The high liquid level float prevents liquid from entering the outlet.

• Inlet solenoid valve with bypass back check valve. The solenoid valve, in conjunction with the high liquid level switch, closes the inlet preventing the liquid from spilling over into the outlet.

• Bottom steam feed protects against freeze up. The condensate is constantly warmed by incomming hot steam. Even if the vaporizing temperature in the shell falls below freezing, there is no risk of the condensate freezing with the resultant bursting of the tube.

• ASME stamped safety relief valve. Each vaporizer unit is adequately protected in accordance with NFPA 58 and California Title 8 codes.

• All sizes ara capable of infinite turndown and will maintain a ready supply of vapor from zero load to full capacity.

• Standard electrical configuration Class I, Division I.

• Vertical design provides maximum capacity in a compact unit.

Performance

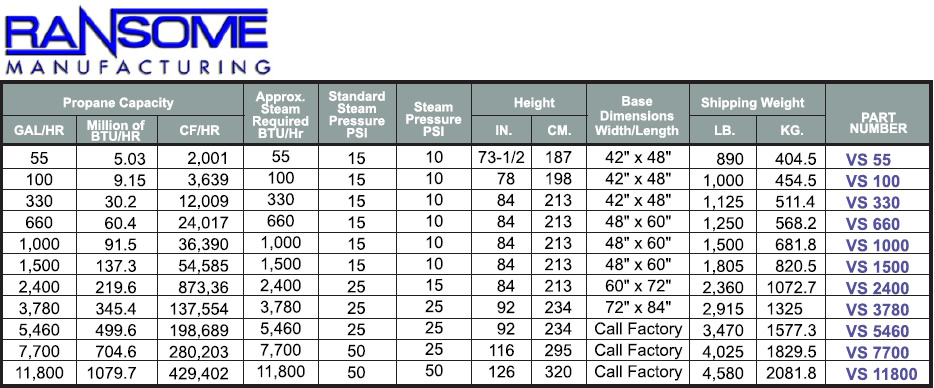

Rated capacity in GPH of Propane at 0 degrees F with a minimum vapor outlet temperature of 100 F. (Note: Rated capacity for butane and other LP-Gas mixtures will be lower than that of propane.) For units operating on hot water (180 F) capacity is reduced approximately 50%.

Operating Temperature Range: 80-140 F

LP-Gas Safety Relief Valve Setting: 250psig

Steam Relief Valve Setting (15 psig steam): 50 psig

Design pressure, LP-Gas side: 250 psig

Design pressure, Steam side: 100 psig

Design Temperature: 650 F

The high liquid level float breaks on liquid rise.

Base and Frame: Carbon Steel structural channel

Vap. Vessel Shell: Carbon Steel

Vap. Tube Bundle: Stainless Steel

Connections: Carbon Steel