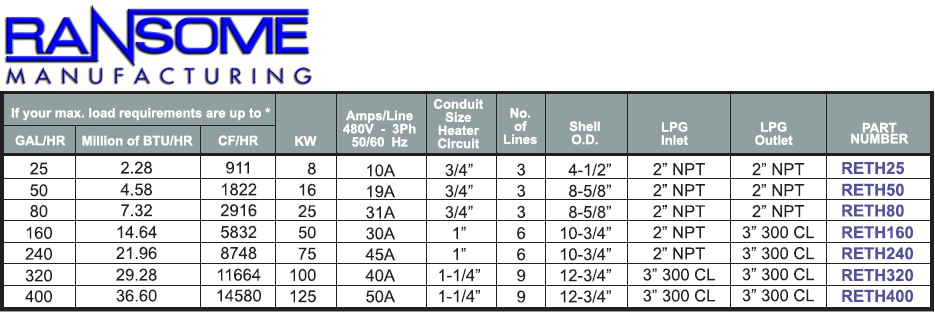

Description

Features and Benefits

• ASME Code Pressure Vessel. Each vessel is constructed of high strength carbon steel as per Section VII, Div. I of the ASME Code.

• Precision operating and safety limit switches.

• Top quality flanged immersion heater. Steel elements are standard. Stainless steel available. Heaters are sized for the exact heat required.

• ASME stamped relief valve. ASME preesure vessel is adequately protected by an external safety relief valve.

• All controls (contactors, relays, etc.) are located inside a NEMA 4 control panel for dependable performance even in extreme weather conditions.

• All sizes are capable of infinite turndown and will maintain heat supply and resultant pressure in LPG storage vessel from zero load to full capacity. At no load, only enough heet will be generated to maintain set point pressure.

• Standard electrical configuration Class I, Div. II. (Class I, Div. I also available)

Control

The RE Series Tank Heater uses pressure actuated ON/OFF control to maintain a desired pressure in the LPG storage vessel. An operating pressure switch cycles an immersion heater full ON or OFF. Pressure sensitivity (hysteresis) is designed into the control action between ON and OFF. This sensitivity is designed to prevent the switching of the immersion heater ON and OFF within a pressure span that is too narrow. Pressure is always maintained “about the set point”. This is dictated by the switching sensitivity of the ON/OFF control. The control action further dictates that there will be a certain amount of pressure overshoot and undershoot. The degree of overshoot and undershoot will be dependent on the characteristics of the entire thermal system.

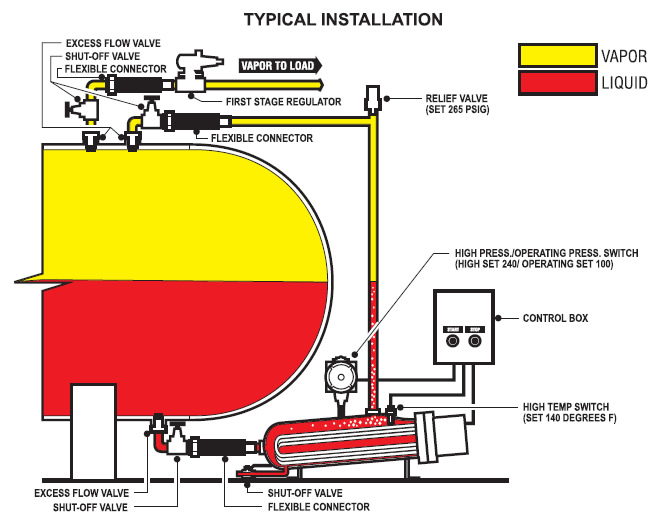

Operation

The RE Series Tank Heater is installed as close to and as far below the LPG storage tank as practical. This is very important since the tank heater is dependent on gravity for the flow of LPG liquid into it. The shortest possible run of adequately sized supply piping minimizes pressure drop and maximizes the value of liquid head pressure to the tank heater. As liquid flows into the tank heater, it is immediately vaporized by the warm immersion heater. The resultant warm vapor is naturally re-circulated back into the LPG storage vessel. This addition of heat raises the temperature and consequently raises the pressure in the system. As system pressure varies due to rise and fall of ambient temperature or vapor withdrawal from tank, the tank heater will circulate sufficient LPG to maintain desired set point pressure as long as heat losses do not exceed capacity of tank heater input.

Note:

1. All control circuits 120v AC, 50/60 Hz 10A

2. Consult factory for large sizes.