Description

Standard Feature

• Mechanical liquid inlet valve provides positive control of LP-Gas liquid level on all RH50, 80 and RH120 sizes. Larger sizes use reliable float switch and electric inlet valve to prevent liquid carryover.

• Millivolt-powered gas control system maintains consistent vapor temperature under changing load conditions.

• Gas control valve is located inside the protective dry cabinet with the regulator mounted on the exterior providing for total ventilation.

• Precision operating temperature switch, factory-set and sealed against tampering, incorporates precious metal contacts for extended service life.

• Two-stage pressure regulation provides accurate burner gas burner pressures and performance regardless of changes in inlet pressure.

• ASME code vaporizing tubes with integral heat exchange vanes and insulated ducts provide efficient vaporization with minimum burner input.

• All sizes are capable of infinite turndown and will maintain a ready supply of vapor from zero load to full capacity. At no load, only enough heat will be generated to maintain vapor temperature and to prevent condensation.

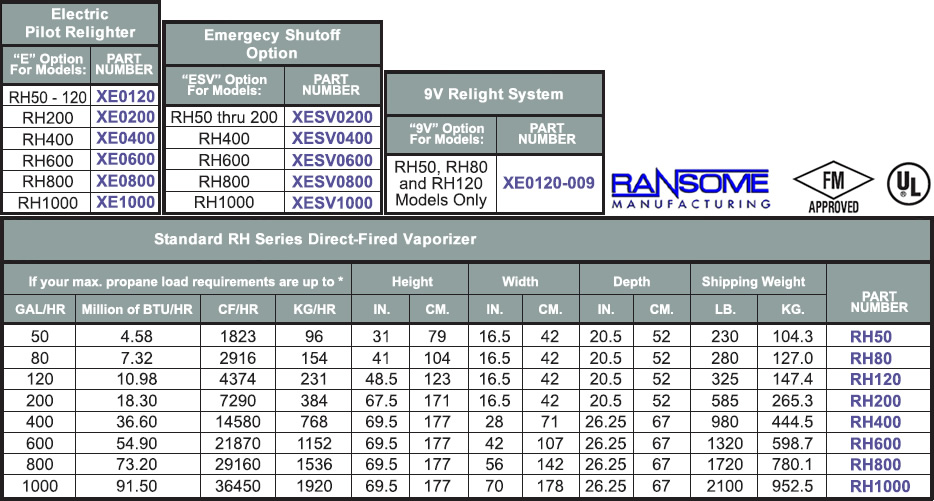

9V Relight System with Solar Recharger

The Ransome 9V Relight System protects against pilot outage due to unusually turbulent atmospheric conditions. The 9V Relight System option is for use in the field where 110V line power is unavailable. Unit operated by two 9V batteries and Solar Panel.

Emergency Shutoff Valve

Vaporizers Pre-Plumbed with Remote Thermal Elements for Pneumatic Means of Safety Shut-Down.

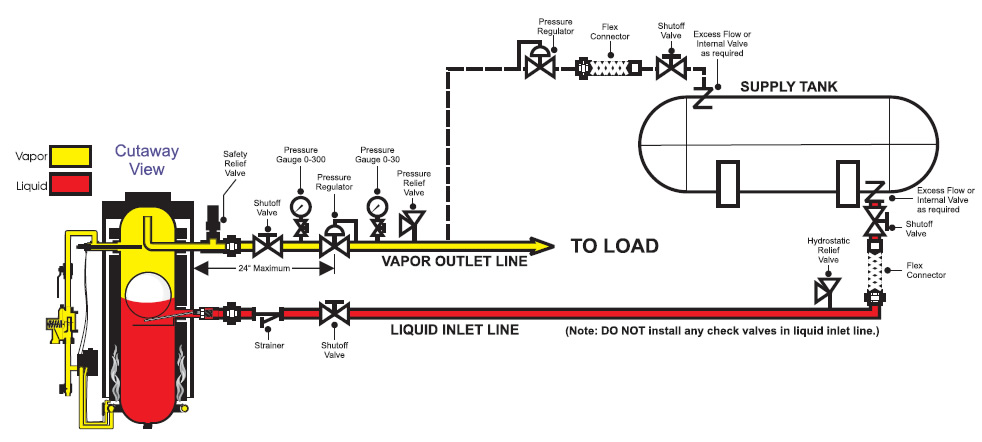

TYPICAL INSTALLATION

1. Equipment, piping and installation must be in accordance with provisions of NFPA58, and all applicable state, provincial and local codes.

2. Liquid pump may be required to provide sufficient pressure to inlet of vaporizer during conditions of low tank pressure.

3. Outlet pressure regulator should be no more than 24 Inches from vaporizer outlet and located at or above centerline of vaporizer outlet.

4. Do not install a separator, dripleg or other liquid trap upstream of outlet pressure regulator.

5. Regulator outlet pressure must be adjusted to a pressure below the vapor pressure of the saturated LP-Gas at lowest operating temperature or vapor may re-liquefy in downstream piping.

6. Liquid piping system must allow for occasional reverse flow toward supply tank to prevent excessive pressures during operation.

(1) Units may be paralleled to achieve greater capacities.

Note: For usage with other gases, consult factory for sizing information. (i.e. C3H6, NH3, SO2, C12)